Engine Oil Pump High Quality for J Eep Wrangler Grand C Herokee D Odge Charger Challenger Aluminum Casting Part

Package size per unit product 8.00cm * 10.00cm * 15.00cm Gross weight per unit product 0.700kg

Basic Info

| Model NO. | YH004 |

| Engine Type | 4 Stroke |

| Car Model | Jeeps |

| Fuel | Gasoline |

| Body Material | Aluminium |

| Component | Fuel Filler Cap |

| Certification | ISO9001 |

| Stroke | 4 Stroke |

| Cylinder | Multi-cylinder |

| Fuel Saver Type | Additive Burning with Fuel |

| Carburettor Type | Downdraft |

| Transport Package | Original Packing |

| Specification | standard size |

| Trademark | Yihu |

| Origin | China |

| HS Code | 8609 |

| Production Capacity | 50000 Pieces/ Per Week |

Packaging & Delivery

Package size per unit product 8.00cm * 10.00cm * 15.00cm Gross weight per unit product 0.700kgProduct Description

| Basic Info: | |||

| Model NO. | YH0001 | Material Inspection Report | Material Inspection Report |

| Dimension Report | Dimension Report | MOQ | Customized |

| Produce | Casting | Color | Customized |

| Size | Customized | Surface Treatment | Drilling, Milling, Other Machining Service |

| Pressure Chamber Structure | Vertical | Tolerance Grade | 7 |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Dr | Drawing Format | STP Igs Dxf Pdf |

| Casting Surface Quality Level | 2 | Certification | CE RoHS ,ISO 9001:2008 |

| Surface Tolerance | 0.1-0.2 | Surface Roughness | Ra1.6-3.2 |

| Design Software | Solid works | Inspection | 100% Before Packing |

| Mold Life | 10000shots | Mold Lead Time | 40-60days |

| Cavity Material | Fsh13 | Transport Package | Carton, Wood Box, OEM |

| Specification | OEM ODM | Origin | China |

| HS Code | 8480410090 | Production Capacity | 50000/Month |

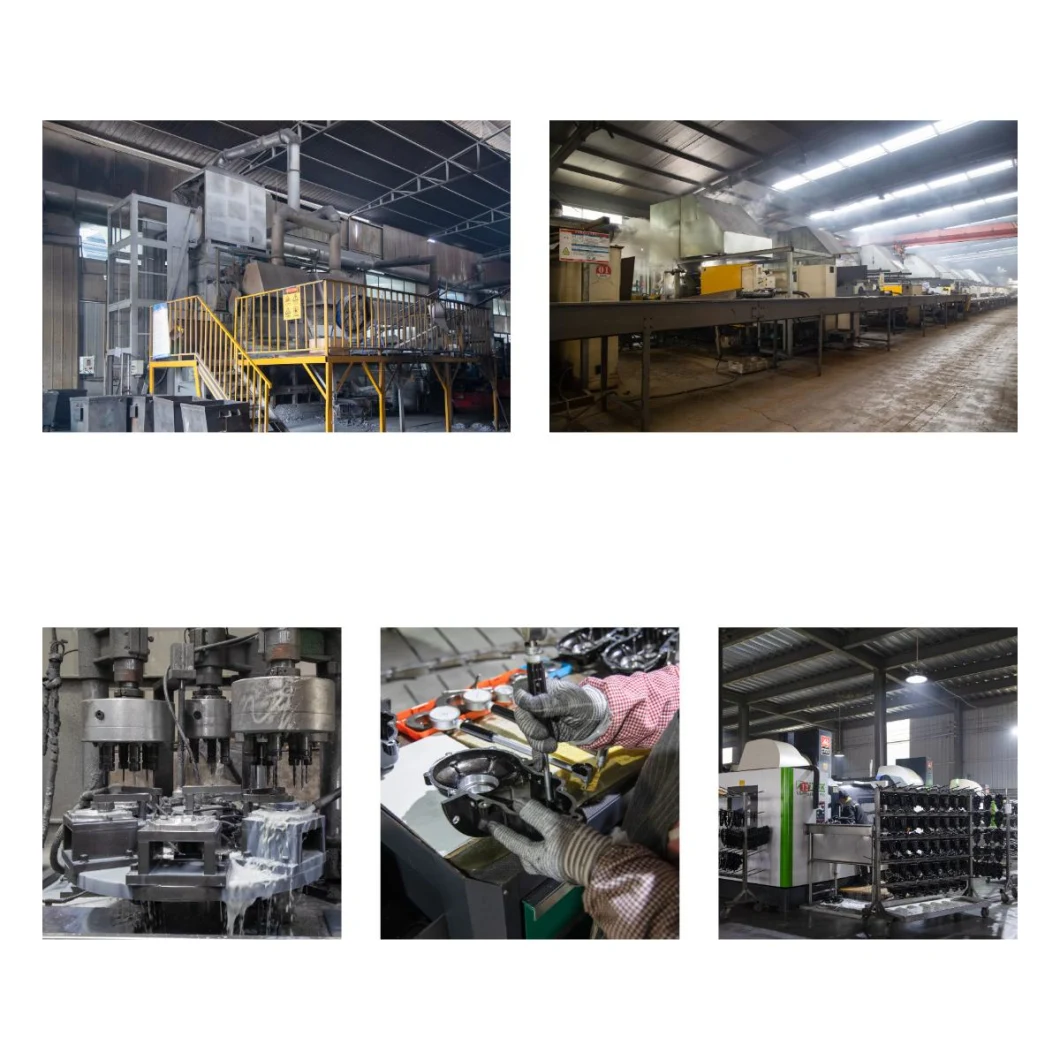

| As professional manufacturer of high precision parts and die casting products, with own R&D department, we can offer OEM service,ODM service.From the below sheet ,you can know us better. | |||

| Material | Aluminum alloy ADC10 . ADC12 . A 360 . A380 . | ||

| Process | Sand casting, Gravity casting, high pressure die casting, low pressure die casting and CNC Machining casting. | ||

| Designs | 1.As per the customer's drawings2.As per the customer's samples | ||

| Equipment of Casting | 1.High pressure die casting machining: 125T/180T/250T/280T/500T/800T/1250T2.Gravity casting machine: 6 production lines3.Low pressure die casting machining: 3 production line4.Sand casting machine: 4 production lines5.Degassing equipment and opportunities to refine the material6.Machining: 10Sets CNC Machines;4 sets Milling machines; 7 sets Turning machines; 15sets drill and tap machines | ||

| Testing facility | spectrometer, tensile test machine, hardness test machine, CMM dimension machine | ||

| Certificate | ISO9001:2008/RoHS/SGS | ||

| Standard | ASTM, DIN,JIS, EN, ISO, GB standards | ||

| Software | Pro/E,UG, Solidworks, Auto CAD, PDF | ||

| Precision machining | CNC turning, milling, drilling, grinding, cutting, reaming and threading | ||

| Finished | Polishing, sand blasting, heat treatment, painting, powder coating, anodizing, electroplating, Chrome plating, mirror polishing. | ||

| Product | All kinds of aluminum casting: include automotive parts, railroad parts, medical parts, marine parts, lighting parts, pump body, valve parts, architectural parts and furniture parts so on. | ||

| Advantage | 1.With more than 20years experiences in Aluminum casting; | ||

| 2.Have four casting types; | |||

| 3.Near Sea Port and Air Port; | |||

| 4.Passed ISO9001:2008/Rosh/SGS | |||

| 5.From Casting to Finished surface, Owned casting, polishing and plating workshops, We can offer Good quality and strict delivery time. | |||

| 6.With samples and order: We can offer dimension report, Chemical composition and Mechanical properties | |||

| 7.Control material with spectral and thermal analysis equipment (density and processing) | |||

| 8.Spectral analysis of raw material and liquid melt, batch before casting. | |||

Send to us