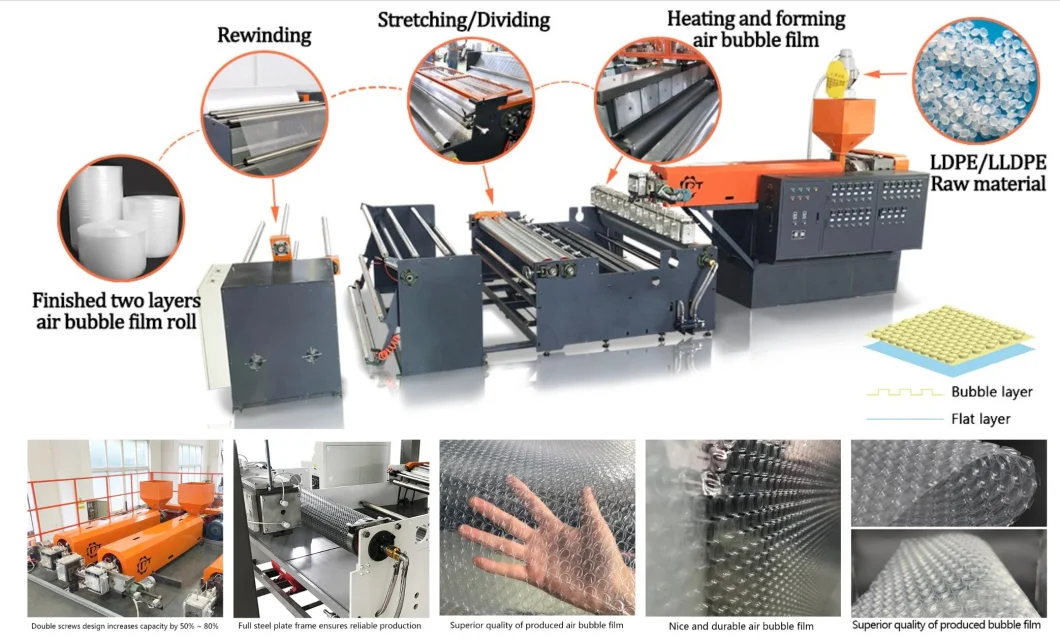

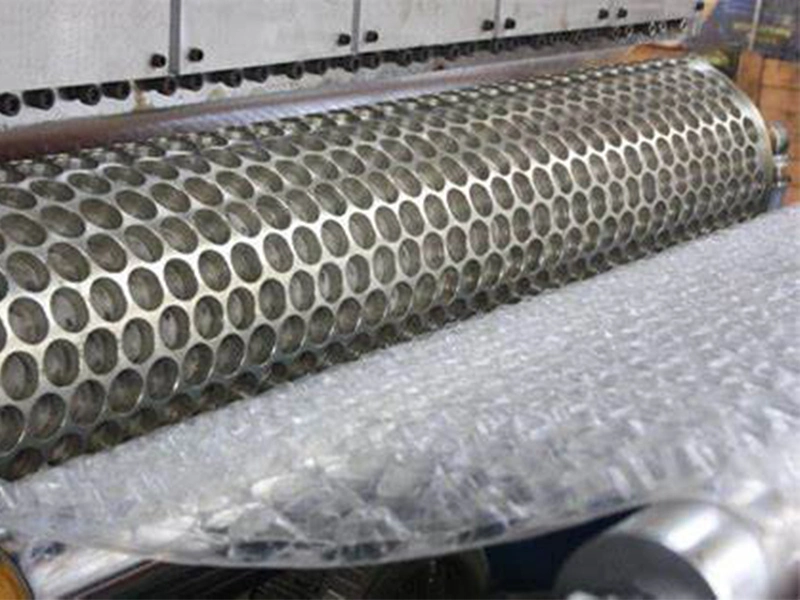

Plastic Extrusion Machine Line Produce Bubble Film Packing Wrap for Transportation Package Avoid Impact

Basic Info

| Model NO. | PLSS |

| Assembly Structure | Integral Type Extruder |

| Screw | Single-Screw |

| Automation | Automatic |

| Application | Bubble Pack |

| Transport Package | Plastic Film Cover |

| Trademark | POLYSUN |

| Origin | Tongling, Anhui, China |

| HS Code | 8477209000 |

| Production Capacity | 200 |

Product Description

| Model | PL-1000 | PL-1200 | PL-1500 | PL-2000 |

| Screw diameter | φ60mm | φ65mm | φ75mm | φ90mm |

| Screw L/D | 30:1 | 30:1 | 30:1 | 30:1 |

| Film width | 1000mm | 1200mm | 1500mm | 2000mm |

| Max. output | 50kg/h | 66kg/h | 80kg/h | 100kg/h |

| Extruder power | 15kw | 15kw | 18.5kw | 37kw |

| Total power | 28kw | 38kw | 50kw | 80kw |

| Power supply | 380V, 50 Hz, 3 phases (customizable) | |||

| Weight | 4000kg | 4200kg | 4500kg | 7000kg |

| Dimensions (L*W*H) | 9*3.5*2.5m | 9.5*3.8*2.5m | 10*4*2.8m | 11.5*4.8*4m |

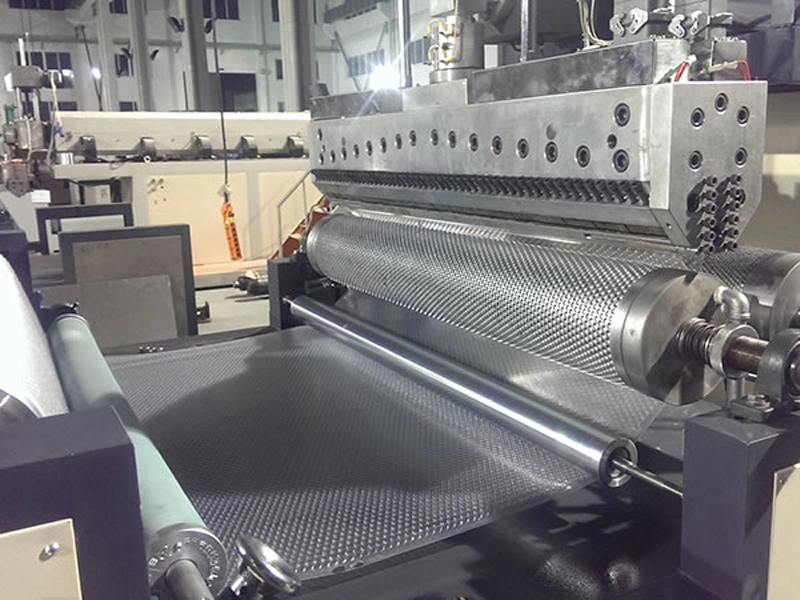

Air Bubble Film: The air bubble film is made of low-density polyethylene(LDPE) material. It is a frequently used packaging material. Its function is to form air bubbles in the double-layer plastic film to prevent impact and squeeze and serve as a buffer to protect the packaging products. At the same time, the bubble film also has the function of heat insulation. Because the bubble is filled with air, the bubble film has the advantage of being lightweight and transparent. It is widely used in packaging products or filling gaps in all walks of life.The bubble film has single-layer bubble film and double-layer bubble film. Single-layer bubble film is composed of one layer of film and one layer of bubbles. This kind of bubble film is full of bubbles and is suitable for packaging various purposesAir Cushion Film: The main raw materials for the extrusion of the air cushion film are low-density polyethylene, high-density polyethylene, and linear polyethylene. If the air cushion film requires a color, an appropriate amount of colorant should be added to the resin.

Certifications

FAQ

Q: Are you a trading company or factory?

A: We are a factory with a foreign trading department. We manufacture the plastic extruder machine by our own factory. So don't worry about the after-sell services.

Q: Where is your factory? How do I get there?

A: Factory address: Xingda Industrial Park, No. 720, North Section of Tongdu Avenue, Tongling City, Anhui Province, China. You can take a plane to Hefei Xinqiao International Airport or Nanjing Lukou International Airport, we can arrange the pick-up. Or you can take the high-speed rail to Tongling Station.3.

Q: In what year was your company founded?

A: Our company was founded in 2012, the founder Mr. Yuan Xu has been engaged in the plastic machinery and mold processing industry for more than 20 years.4.

Q: What payment methods do you support?

A: We support T/T, Western Union, PayPal, and other payment methods.5.

Q: What shipping methods do you support?

A: Sea transportation, air transportation, railway transportation, and road transportation, etc. Usually, we go by sea.6.

Q: What is your packaging?

A: Our conventional packaging is: Wrap the plastic film around the machine, and then put the machine in a wooden box.7.

Q: What is your delivery time?

A: Generally speaking, the delivery time of a production line is about 50 days.8.

Q: How is your after-sales service?

A: Our equipment has an 18-month warranty and supports lifetime maintenance. We have a strong technical service team.