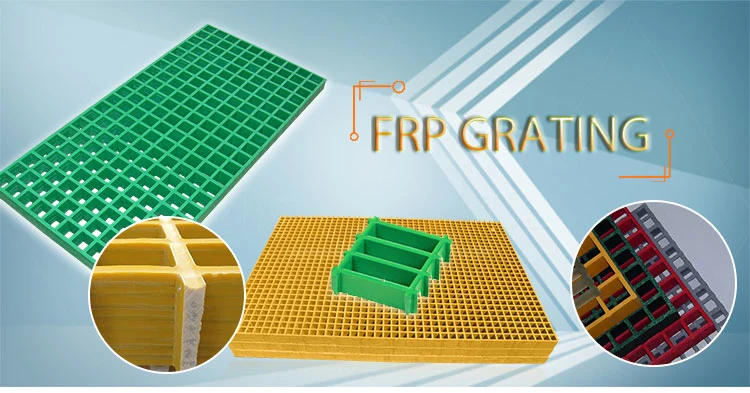

Wholesale FRP Grating Drain Grate Floor Plastic Drainage Grate Fiberglass Panel Trench Cover

Basic Info

| Model NO. | LT-20210422 |

| Fiberglass Type | E-Glass |

| Certification | BSCI |

| Technique | Spray Up Roving |

| Transport Package | Common Packing&Deliver |

| Specification | 38*38*38MM, 40*40*40MM, 50*50*50MM |

| Trademark | Longtime |

| Origin | Hebei |

| HS Code | 3926909090 |

Product Description

Hot selling FRP grating drain grate floor grating plastic drainage grate fiberglass grating panel,GRP trench cover

Product Description

About FRP Grating:

FRP molded grating/ fiberglass plastic grating As a new product, FRP grating has the advantages of high strength and light weight. It is suitable for many industries, such as poultry farming, car wash house, tree grate, power plant, trench cover, sewage treatment plant, etc.

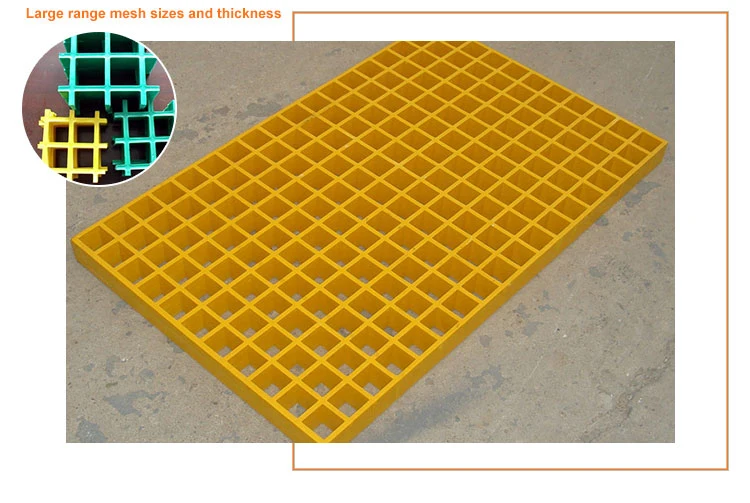

FFRP Molded grating size:

No. | Mesh/Thick (mm) | Thick (mm) | Open Area (%) | Weight (KG/m2) | Panel size (mm) | Usage |

1 | 38mm x 38mm | 25mm | 68% | 12.5kg | Customzied | Pedestrian walkway, trench cover plate, tree cover, breeding |

2 | 30mm | 68% | 16kg | Customized | Machine Platform | |

3 | 38mm | 65% | 20kg | Customized | Car Wash Room | |

4 | 40mm x 40mm | 25mm | 67% | 11.5kg | Customized | Pedestrian walkway, trench cover plate, tree cover, breeding |

5 | 30mm | 67% | 14kg | Customized | Machine Platform | |

6 | 38mm | 67% | 18kg | Customized | Car Wash Room |

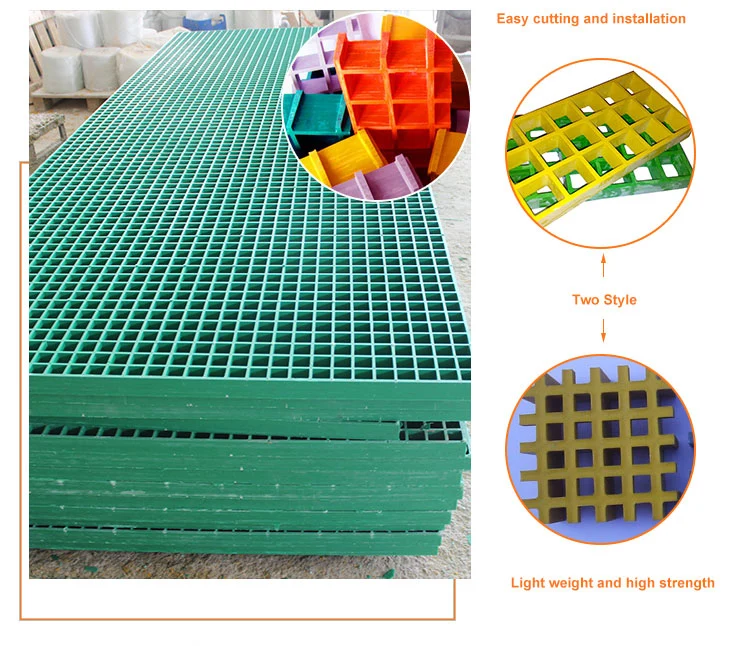

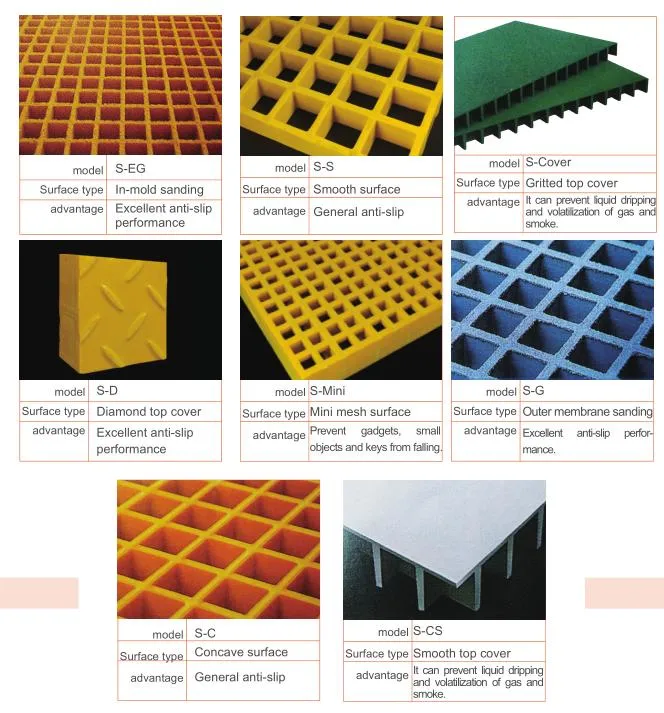

FFrp molded grating surface:

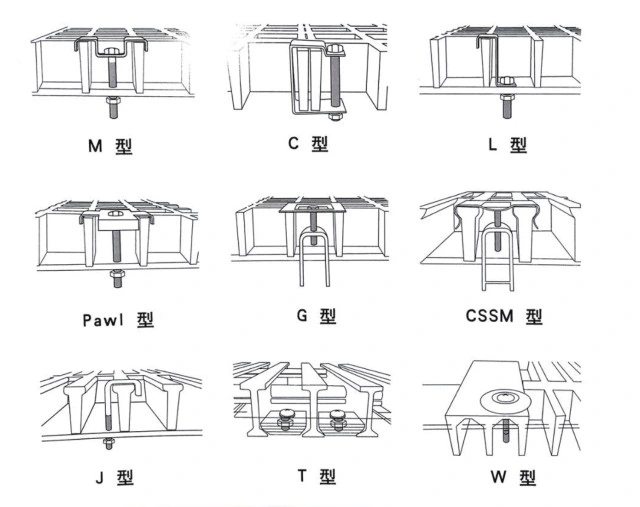

FRP Molded grating clip:

Hot selling FRP grating drain grate floor grating plastic drainage grate fiberglass grating panel,GRP trench cover process:

1. Stirring raw materials

Resin, fiberglass fiber yarn, calcium powder filling, color paste, reagents, etc. are arranged in proportion, stirring for 20 minutes.

2. Pouring material

Pouring the mixed raw materials onto the mold machine corresponding to the FRP grating.

3. Draw yarn

Lay the alkali-free yarn layer by layer to improve the strength of the FRP grating.

4. Compression mold

The stirred raw materials are poured into the mold and compacted mechanically or manually.

5. Heat curing

After the grating is heated for 20 minutes, the raw materials and yarn are fused together.

6. Cooling demoulding, mold lifting

After the above process is completed, cooling for 10 minutes demolding, mold lifting, semi-finished grating finished.

7. Grinding, painting and washing

The FRP grating is polished and washed with a layer of varnish or water.

FRP Molded grating packing:

FRP molded grating application:

FRP molded grating factory:

If you are intersted in our goods please contact as below information:

Zaoqiang Longtime FRP product company Add:FRP industry zone,Hebei,China