CNC Turning-Milling 4 Axis Machining Customized Aluminum Stainless Steel Brass Parts

Basic Info

| Model NO. | AMC1004 |

| After-sales Service | Yes |

| Warranty | 1 Years |

| Condition | New |

| Certification | CE, RoHS, GS, ISO9001 |

| Standard | DIN, ASTM, GOST, GB, JIS, ANSI, BS |

| Customized | Customized |

| Material | Aluminum |

| Application | Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery |

| Tech | CNC Machining |

| Processing | Aluminum Die Casting |

| Transport Package | Carton and Pallet |

| Specification | customized |

| Trademark | Made In China |

| Origin | China |

| HS Code | 7616999000 |

| Production Capacity | 30000PCS/Month |

Product Description

CNC Turning-Milling 4 Axis Machining Customized Aluminum Stainless Steel Brass Parts

- Technology: aluminum CNC machining, aluminum die casting.

- Machine: CNC lathe, CNC milling, drilling etc.

- More Available Aluminum die Casting Information:

| Material | Aluminum alloy, Aluminum extrusion, copper etc. |

| Casting process | Aluminum die casting , Aluminum sand casting, Aluminum gravity casting, permanent mold casting, high pressure die casting, low pressure die casting, ect. |

| Machining method | turning , milling, drilling, grinding, threading, CNC machining, etc. |

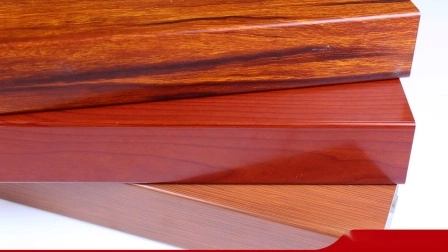

| Surface treatment | sand blasting, shot blasting, polishing, plating, acid treatment, anodized, painting, powder coating,passivating,E-coating(or electrophoretic paint),electropolishing ect. |

| Tolerance | CNC machining dimension +/-0.01mm(or according to drawing request, special size respect) |

| Application | Industrial machinery parts, Marine hardwares, Pipe Fitting Parts, Textile machinery parts, Sport facility parts, Pneumatic tools parts, Fluid equipment parts, Copper alloy parts, Food machinery parts, Auto parts, Elevator Parts, Air compressor Parts, Electric machine & hardware fittings, Mining & earthmoving machinery accessories, pump body and valve |

| Production flowchart | Drawing or Sample→Mold Making→Making Samples→ Die Casting→ Deburring→ Machining→Surface Treatment→ Assembly→Quality Inspection → Packing → Delivered |

CNC Turning-Milling 4 Axis Machining Customized Aluminum Stainless Steel Brass Parts

1. Products individually by bubble bag or PE,poly bag et.

2. Good quality double corrugated carton pack by Grade A, each carton is no more than 15kgs or 35lbs.

3. Pallet or wooden case

The company is professional manufacturer of metal products,that are used in a kind of industry,as auto,electronical,household and more. The company has a large production capability, strong technical force and first-rate test facilities as well as a team of high quality staff and workers, and is run with the authentication of ISO9001:2008 quality system. Our products are widely sold to all over the world, Europe, America, Africa, Asia and other countries.

The company based on the enterprise spirit of development, solidarity, honesty, pragmatic approach, innovation and exploration and insisted the operation philosophy of quality uppermost, customer and honor in number one position. The target is to fully promote its levels in the fields of design, process and manufacturing.

Our Advantages

We are manufacturer, and we are certified to ISO9001 quality management system.

Good Faith, Express, Quality is the priority,Efficiency.

CNC Turning-Milling 4 Axis Machining Customized Aluminum Stainless Steel Brass Parts

Q1: How to get the quotation?A1: For quotation we need the customer to offer the drawing like 2D, but if you have the 3D or sample would be better, usage information, material request, surface treatment and other technologic which needs to pay attention and other information which will affect the quotation.

Q2: How long will finish the quotation? A2: Normally it will need 1 to 5 days.

Q3: Can you produce the parts according to the samples? A3: Yes, we have the reverse engineering capability.