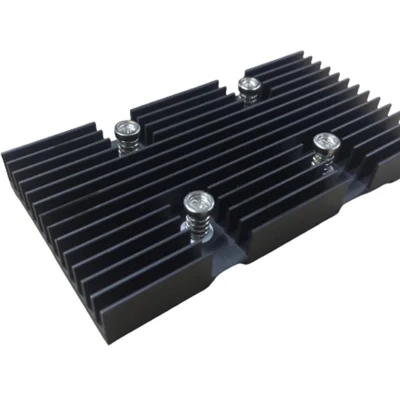

Customized Aluminum Anodized Extruded Heat Sink with CNC Machining

Aluminum heat sink extrusion is the most common process and cost efficient thermal solution for most electronic devices

Basic Info

| Warranty | 1 Year |

| Condition | New |

| Certification | CE, RoHS, ISO9001, ISO14001 |

| Customized | Customized |

| Material | Aluminum |

| Application | BGA, IGBT, LED, Inverter,etc. |

| Transport Package | Tray, Carton |

| Specification | customized |

| Trademark | Sinda Thermal |

| Origin | China |

| HS Code | 7403111100 |

| Production Capacity | 100000/Month |

Product Description

Aluminum heat sink extrusion is the most common process and cost efficient thermal solution for most electronic devices and industrial applications. Aluminum extruded heat sink has lightweight, good thermal performance, cost-efficient, easily manufacturing, etc. benefits. The aluminum extruding process is to put the heated aluminum ingot to the customized tooling die to get the designed shape and dimensions, then cut off the extrusion profiles to get the wanted length; usually the further processes such as CNC maching, drilling, anodizing are needed to complete the custom design and dimensions.

Product specifications

| Material | Aluminum alloy | Certificates | ISO 9001:2015,ISO 14001:2015 |

| Product dimension | Customized | Type | Extruded heat sink |

| Process | Extruding, CNC, drilling | Lead time | 2-3 weeks |

| Surface finish | Anodizing | Packing | Tray, carton |

| OEM/ODM | Yes | Quality control | 100% |

| Application | CPU, inverter,IGBT,LED,BGA,etc. | Warrantly | 1 year |

Varieties of heat sink

Thermal simulation

Factory and workshop

Certificates

Sinda Thermal is a leading thermal manufacturer in China, our factory was founded in 2014, and located in Dongguan city, China, we are offering varieties of heatsinks and other precious metal parts. Our plant possesses 30 sets advanced and high precious CNC machines and stamping machines, also we have many testing and experiment instruments and professional engineering team, so our company can manufacture and provide high quality products with high precision and excellent thermal performance. Sinda Thermal is devoted to a range of heat sinks which are widely used in new power supply, New energy vehicles, Telecommunications, Servers, IGBT, and Madical. All the products accord with Rohs/Reach standard, and the factory is qualified by ISO9001 and ISO14001. Our company has been a partner with many customers for good quality, excellent service and competitive price. Sinda Thermal is a great heat sink manufacturer for the global customers .

FAQ

1.

Q: Are you a trading company or manufacturer?

A: We are a leading heat sink manufacturer, our factory has been founded over 8 years, we are professional and experienced.

2.

Q: Can you provide OEM/ODM service?

A: Yes, OEM/ODM are available.

3.

Q: Do you have MOQ limit?

A: No, we don't set up MOQ, prototype samples are available.

4.

Q: What's the lead time of the production?

A: For prototype samples, the lead time is 1-2 weeks, for mass production, the lead time is 4-6 weeks.

5.

Q: Can I visit your factory?

A: Yes, Welcome to Sinda Thermal.

Send to us