Extruder Machine Plastic High Impact Polystyrene (HIPS) Extrusion

ABS HIPS Bladder for refrigerators Sheets Plate Making Machine Co-Extrusion Line This line is widely used for home appli

Basic Info

| After-sales Service | 1year |

| Type | Sheet Extruder |

| Plastic Processed | ABS |

| Product Type | Profile Extrusion Molding Machine |

| Feeding Mode | Multiple Feed |

| Assembly Structure | Integral Type Extruder |

| Screw | Single-Screw |

| Engagement System | Intermeshing |

| Automation | Automatic |

| Computerized | Computerized |

| Main Electrical Parts | ABB, Omron, Rkc, Schneider, FUJI, Delix etc. |

| Customized | Customized |

| Application | Housing Waterproof, Architecture Engineering |

| Model No | Lsj-150/90 |

| Board Width | 1220-2100mm |

| Board Thickness | 1-8mm |

| Die Head | T-Type, Jc-Times Brand |

| Transportation | 2X40f Containers |

| Extruder Model | High Efficiency Single Screw Extruder 150/33 |

| Three Roller Calendars | Vertical Type, Alloy Steel Material |

| Transport Package | Wooden Pallets and Cases and Films |

| Specification | 400-800kg/H |

| Trademark | Leader Machinery |

| Origin | Qingdao of China |

Product Description

ABS HIPS Bladder for refrigerators Sheets Plate Making Machine Co-Extrusion LineThis line is widely used for home appliance field,such as internal for refrigerators,out shell for washing machine and air conditioner etc. It can be produced with additives to different requirements such as improving intensity, improving toughness, improving rigidity, flame retardant, embossing, frosting etc.

SHEET FEATURES AND APPLICATIONS:

The sheet retains the features of acrylic surface rigidity and gloss, and also has the advantage of ABS impact resistance.

SHEET SPECIFCATIONS:

thickness: 1-8mm, width: 1220-2100mm

| tem | Description | Data |

| 1 | Raw material vacuum feeding machine | 1 set |

| 2. | Degassing type single screw extruder 120/38 | 1 set |

| 3 | Hydraulic exchanging unit+ melting gear pump | 1 set |

| 4 | T-type die head-JC-times brand | 1 set |

| 5 | Three roller calendar-vertical type, alloy steel material | 1 set |

| 6 | Rollers theromocontrolling machine-oil circulation cooling | 1 set |

| 7 | Cooling frame/rollers conveyor | 1 set |

| 8 | Trimming units-cross saw cutting units | 1 set |

| 9 | Haul off machine-2 pieces of NBR rubber rollers | 1 set |

| 10 | Plastic cutting machine-guillotine and saw cutting machine | 1 set |

| 11 | Stacker | 1 set |

| 12 | Water chiller | 1 set |

| 13 | Electrical cabinet | 1 set |

COMPANY CERTIFICATIONS OF:COMPANY CERTIFICATIONS OF:OTHER PLASTIC SHEET EXTRUSION LINE RECOMMEDATION

1. PC/PP hollow profile sheet/hollow grid sheet extrusion line

Processing material: PC/PP virgin material plus recycle material

Thickness range: 2mm-4mm-6mm-8mm-10mm-12mm

Net sheet width: 1220mm-2100mm

Layer structure: Single layer or multi-layer

Capacity: 200-600kg/h

Application: Ads. Decoration, roofing, packaging, printing, etc.

2. ABS/HIPS sheet extrusion machine:

Processing material: ABS/HIPS virgin pellets plus recycle material

Thickness range: 1-6mm

Net Sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 400-800kg/h

Application: Vacuum forming, thermoforming, refrigerator inner layer, suitcase, etc.

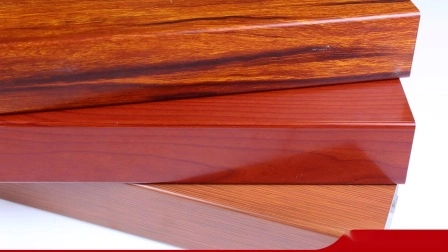

3. ABS/PMMA sheet extrusion machine:

Processing material: ABS/PMMA virgin pellets plus recycle material

Thickness range: 1-8mm

Net sheet width: 1200mm-1600mm-2100mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity: 400-800kg/h

Application: Vacuum forming, bathtub, etc.

4. PP PE foam board/sheet extrusion line

Processing material: PP, PE , Foam additives, master batch

Thickness range:0.8-3-12mm

Net sheet width: 600mm-1260mm-

Layer structure: Single layer or double layers (A/B), three layers (A/B/A, A/B/C)

Capacity: 150-500kg/h

Application: stationery, containers, handbags, heat insulation material, construction, food packing, automobile area, industry application, sports fields etc.

5. PE HDPE sheet extrusion machine:

Processing material: HDPE/LDPE/LLDPE virgin pellets plus recycle material

Thickness range: 1-2.5mm, 3-35mm

Net sheet width: 1200mm-1600mm-1800mm-2500mm-3000mm-40000mm-6000mm-8000mm

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1200kg/h

Application: Packaging, construction, water-proof, water-drainage, Geomembrane film, etc.

6. PC/GPPS/PMMA sheet extrusion machine:

Processing material: PC/GPPS/PMMA virgin pellets plus recycle material

Thickness range: 1-12mm

Net sheet witdh: 600mm-1220mm-2100mm(or as per customer's requirement)

Layer Structure: Single layer or multi-layer

Capacity: 400-600kg/h

Application: Ads., decoration, roofing, etc.

7. PP/PS sheet extrusion machine:

Processing material: PP/PS virgin pellets plus recycle material;

Thickness range: 0.15-2mm

Net sheet width: 650mm-720mm-1000mm-1300mm-1500mm(or as per customer's requirement)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-1000kg/h

Application: Thermoforming(cup, bowl, etc. ), stationery, printing sheet, packaging, etc.

8. PET sheet extrusion machine:

Processing material: PET virgin pellets(APET or PETG) plus flakes; Or 100% flakes

Thicknes range: 0.2-1.5mm

Net sheet width: 650mm-1500mm(or as per cusotmer's requirement)

Layer structure: Signle layer or multi-layer

Capacity: 150-500kg/h

Application: Thermoforming(cup, bowel, etc. ), stationery, printing sheet, packaging, etc.

9. PVC sheet/edge banding sheet/marble sheet machine:

Processing material: PVC power plus other additive

Thickness range: 0.15-1mm; 1-3mm; 3-12mm

Net sheet width: 650mm-2000mm-3000mm( or as per customer's requirements)

Layer structure: Single layer or multi-layer

Capacity: 200kg/h-500kg/h

Application: Thermoforming, stationery, printing, payment card, SIM card, construction, etc.

10. EVA car interior decoration sheet extrusion line

Processing material: EVA and other additives

Thickness range: 1-8mm

Width range: 1000-1800mm

Layer strcuture: single layer

Capacity: 500-800kg/h

Application: automotive sealing strips, sound insulation cushion, sound absorption sheets,

automobile tail box, fenders, car interior and exterior decoration parts etc.

11. PVC+PMMA Glazed roofing tiles/corrugated sheet extrusion machine

Processing material: PVC, PMMA and other additives

Thickness range: 1-8mm

Width range: 720mm, 880mm, 1040mm

Layer structure: A/B, A/B/A, A/B/C

Capacity: 400kg/h

Application: garden-style factory, tourist scenic spots, pavillions, hotels, family building etc.

Send to us